Rare earth magnets are among the most powerful permanent magnets available today, prized for their exceptional strength and compact size. These magnets, primarily composed of neodymium or samarium-cobalt alloys, deliver magnetic performance far beyond that of traditional ferrite or alnico magnets. Their unique properties have made them essential components in a wide range of modern devices, from consumer electronics to renewable energy systems. Understanding the applications of the strongest rare earth magnets highlights how these small but powerful materials drive technological innovation and efficiency across industries.

Rare Earth Magnets and Their Distinctive Properties

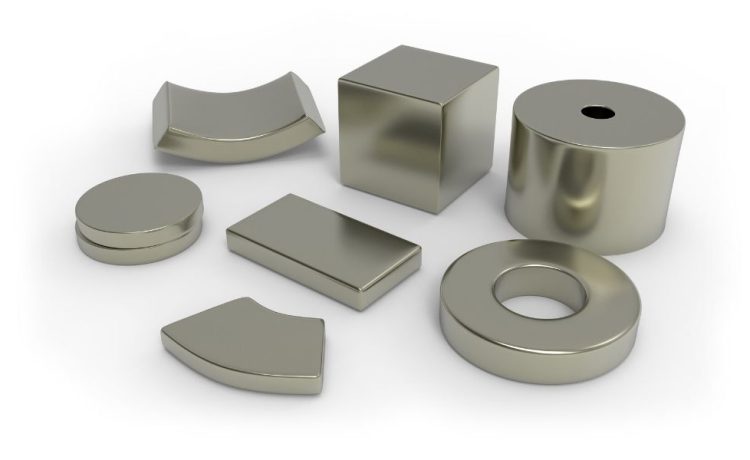

The strongest rare earth magnets are defined by their high magnetic flux density and resistance to demagnetization. Neodymium magnets, often referred to as NdFeB magnets, are the most widely used due to their remarkable strength and relatively low cost. Samarium-cobalt magnets offer slightly lower magnetic strength but excel in high-temperature environments, making them suitable for specialized industrial applications.

The compact size of rare earth magnets allows engineers to design smaller, more efficient devices without sacrificing power. Their strength-to-size ratio is a critical factor in enabling miniaturization in electronics, medical devices, and transportation systems. Additionally, their durability and resistance to corrosion (with appropriate coatings) make them reliable in demanding environments.

Consumer Electronics and Compact Devices

One of the most visible applications of the strongest rare earth magnets is in consumer electronics. Smartphones, tablets, laptops, and wearable devices rely on compact magnets to enable speakers, vibration motors, and magnetic sensors. In particular, haptic feedback systems in smartphones use neodymium magnets to generate precise vibrations, enhancing user interaction and tactile response.

Wireless charging systems also benefit from strong rare earth magnets. These magnets help align devices with charging pads accurately, ensuring efficient energy transfer. Similarly, magnetic clasps and closures in electronic accessories, such as earbuds and smartwatches, utilize rare earth magnets for secure attachment without bulk. The high magnetic strength allows these functions to operate effectively in tight, compact designs, meeting modern consumer expectations for sleek and lightweight devices.

Renewable Energy and Electric Motors

Rare earth magnets play a vital role in the renewable energy sector, particularly in wind turbines and electric motors. Neodymium magnets are a core component of permanent magnet synchronous generators used in wind turbines, where their high efficiency and compact design allow turbines to generate more power while reducing overall weight. This efficiency is crucial for offshore and high-altitude installations where weight and space constraints are significant.

Electric vehicles (EVs) are another major area where the strongest rare earth magnets are transforming modern technology. EV motors rely on neodymium-based magnets to produce powerful, efficient torque while minimizing motor size and weight. The compact, high-strength magnets enable automakers to design lightweight vehicles with extended battery life and improved performance. This application has significantly accelerated the adoption of electric mobility worldwide, highlighting the magnets’ strategic importance in the automotive industry.

Medical Devices and Precision Equipment

In the medical field, the strongest rare earth magnets are used in precision instruments and diagnostic devices. Magnetic resonance imaging (MRI) machines utilize powerful magnets to generate detailed images of internal body structures. Neodymium and samarium-cobalt magnets are selected for components that require both high magnetic strength and stability under continuous operation.

Smaller medical devices, such as surgical tools and prosthetics, also benefit from rare earth magnets. Their compact strength allows devices to perform precise movements or maintain secure connections in tight spaces. This capability is particularly valuable in minimally invasive procedures where accuracy and reliability are critical.

Industrial Applications and Robotics

Industrial machinery increasingly integrates rare earth magnets to enhance automation and efficiency. Robotics, conveyor systems, and precision manufacturing equipment often incorporate neodymium magnets for motorized components, magnetic sensors, and gripping mechanisms. These magnets enable robots to perform delicate tasks with accuracy while maintaining speed and power.

Magnetic separation and lifting systems in industries such as recycling and metal fabrication also rely on rare earth magnets. Their exceptional strength allows for the handling of heavy or dense materials, improving operational efficiency and safety. By using high-performance magnets, manufacturers can optimize workflows and reduce the footprint of machinery without sacrificing capability.

Emerging Applications and Future Trends

The demand for the strongest rare earth magnets continues to grow as technology evolves. Emerging applications include drone motors, smart home devices, advanced hearing aids, and high-fidelity audio equipment. In each case, the ability to deliver strong magnetic performance in small, lightweight packages is a key enabler of innovation.

Recycling and sustainability are also becoming critical considerations in rare earth magnet applications. Research is underway to recover and reuse these magnets from end-of-life devices, ensuring that industries can continue to rely on their performance while mitigating environmental impacts. Advances in material science may further enhance the strength, temperature resistance, and corrosion durability of these magnets, expanding their utility in new and demanding environments.

The strongest rare earth magnets are indispensable in modern devices, combining compact size with unparalleled magnetic strength. From consumer electronics and renewable energy systems to medical equipment and industrial machinery, these magnets enable performance, efficiency, and innovation across multiple sectors. As technology continues to evolve, the role of rare earth magnets will only grow, underscoring their importance in driving the functionality and advancement of modern devices.